ABB IRB5400-02

The ABB IRB 5400 is engineered to offer precise painting, high uptime, low paint utilization, short cycle times for successful integration. The ABB IRB 5400 is equipped with closed loop regulation and high-speed control for paint and airflow adjustment which leads to diminished overspray and secures an unvarying film build up. The electric motor, articulated ABB IRB 5400 robot can be rail-mounted, with minimal disturbance of booth air flow.

The easily programmed IRB 5400 series of robots have a slim arm, flexible hollow wrist and powerful mechanics and drive systems. The robot is designed with a large work envelope and high load capacity. These characteristics lead to high acceleration and high speeds for the robot. Most applications using the ABB IRB 5400 robot produce uniform performances.

General info

- Axes: 6

- Payload: 15 kg

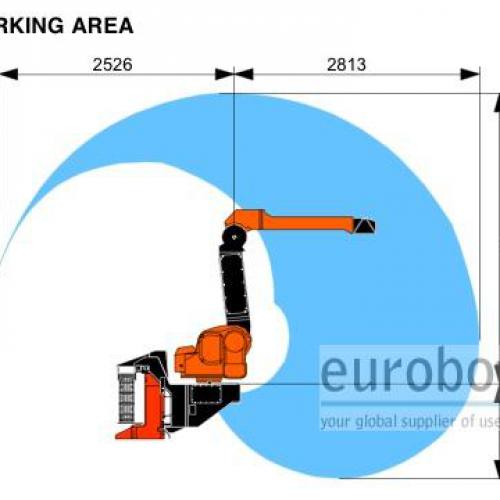

- V-Reach: 1200 mm

- H-Reach: 1620 mm

- Repeatability: ±0.15 mm

- Robot Mass: 790 kg

- Mounting: floor

Additional Robot Information

Robot Motion Range

- Axis 1 ±300°

- Axis 2 ±160°

- Axis 3 ±150°

- Axis 4 ±unl°

- Axis 5 ±unl°

- Axis 6 ±920°

Applications

- Material Handling

- Painting Automation

- Robotic Coating

Robot Controllers: S4P+

Robot Motion Speed

- Axis 1 137 °/s (2.39 rad/s)

- Axis 2 137 °/s (2.39 rad/s)

- Axis 3 137 °/s (2.39 rad/s)

- Axis 4 440 °/s (7.68 rad/s)

- Axis 5 430 °/s (7.5 rad/s)

- Axis 6 600 °/s (10.47 rad/s)

Applications

Pictures

Videos

Diagrams

English

English

Spain

Spain

Germany

Germany

France

France

Russia

Russia

China

China

Argentina

Argentina

Portugal

Portugal

Colombia

Colombia

Italy

Italy

India

India

Brazil

Brazil

Japan

Japan

Mexico

Mexico

Ukraine

Ukraine

Peru

Peru

Sth. Africa

Sth. Africa